Do you know about Mesh? Sounds technical and complicated, but in fact it is simple as ABC! This is a specific type of material called Fc-Cr-Al mesh, which consists of three vital metals: iron (Fe), chromium (Cr), and aluminum (Al). Its mesh is very strong and well made however. High heat and tough conditions are not a problem for it, making it hugely versatile in a variety of applications.

We have so much to discuss about the importance of Fc-Cr-Al mesh for various industries. In the automotive industry, which is a car industry, for example, this mesh is used in parts such as catalytic converters. These pieces are critically important as they must be able to handle the hot gases that flow from the car’s exhaust. Due to the heat resistance of Fc-Cr-Al mesh, this type of material is suitable to perform this role.

Aside from the automotive industry, metal mesh is also available in the aerospace industry, which is the industry responsible for aircraft and spacecraft. This mesh in turn creates parts for the engine that must perform well even when flying at very high altitudes. Fc-Cr-Al mesh can handle it! The conditions up there are quite severe!

Fc-Cr-Al mesh is different from other kinds of mesh materials such as stainless steel mesh or titanium mesh. It has unique qualities that make it better suited for certain tasks. For example, it is really good for resistance with regards to rust, and damage stemming from heat, which is something not all materials can account for. In contrast to stainless steel, Fc-Cr-Al mesh exhibits comparatively superior oxidation and scaling properties in elevated temperature settings.

With that said, Fc-Cr-Al mesh is commonly found in high temperature environments. One such example is glass production. In the process of making glass, this mesh helps hold glass in the furnace, which is where the glass gets heated until it starts melting. The mesh prevents the glass from sticking to the furnace's surfaces, a consideration that has major implications for producing high-quality glass.

Beginners Can Follow The Important tips. First you want to see what kind of heat the mesh will run. That is crucial because temperature has a direct impact on how long the material will last. The hotter it gets, the more it’s capable of degrading over time.

You should also consider the dimensions and form of the mesh that your project requires. But you need to plan whatever size and shape you need, for different applications. Finally, it is worth to mention that you should select a good supplier as Hongshida, to be sure you’re getting a quality product. The right kind of Fc-Cr-Al mesh can be determined with the help of a good supplier.

Fc-Cr-Al mesh have a strong after-sales department, to help our products to be able to resolve customer's problems, we provide a variety of solutions to customers, in order to resolve their issues. When a buyer purchases a product from us, some customers may submit specific packaging requirements. The packaging of our products is done in accordance to the specifications of the customers. If the product is transported to the customer, the product becomes damaged as a result of transportation, or the surface is damaged, etc., our company provides an exchange or return service for free. Customers can feel more confident when buying our products. The repurchase rate of these products is also high.

Our company is certified by the ISO9001 quality system certification to ensure we can provide Fc-Cr-Al mesh and reliable high-quality services and products by focusing on the fundamentals and methods of quality management, which includes quality planning, quality control as well as quality assurance and improvement, and implementing this system to ensure consistency of product quality and improve the satisfaction of customers. And the intention to cooperate with our business. We have a superior quality assurance program, a stringent management system, high manufacturing capacity and cutting-edge testing technologies, to ensure that our products are that are of the highest quality and have a high production capacity at the same time, and also have a strong market competitiveness.

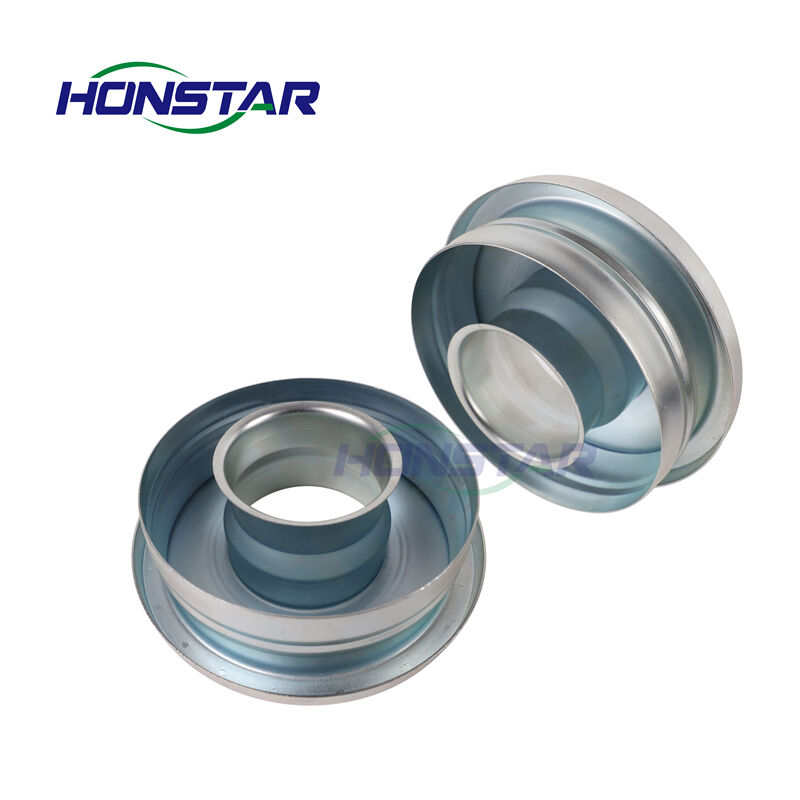

We offer more than 2000 types of products with dimensions and specifications that are similar to most merchandise available. Steel, stainless steel, and other substances are used in the production of the products. The products we offer can be adapted to different application fields, and they play an important part. Our company also offers customized products through the use of molds. The Fc-Cr-Al mesh design and development team has the ability to create products that are customized based on the customer's drawings and following discussions with our mold design team. In addition additional accessories can be attached to existing products in accordance with the specifications of the customers.

Our company's products dominate the majority of the market in this industry in Fc-Cr-Al mesh and the raw materials that we use are guarantee. Since the parts used for stamping are produced with molds the mistakes that can occur in traditional processing methods are avoided, and the product's quality is assured. When making items, it is sometimes based on the characteristics of the material the film is positioned on the surface of the material to avoid imperfections or flaws on the surface of the product. By this method established the basis of the quality of our products. They are also highly appreciated by our clients.