Ever wondered how factories keep the air clean? Well, they also have special bags to do this important job! Mesh are what Hongshida produces, and they are pretty a magic machine that keeps the air safe.

These special bags grab small bits of dust and dirt sparkling through the air. They even can catch nanobags, tiny particles even so small that you can't see them! This is essential because dust and dirt, dirt particles in air make a person sick or cause issues in factories.

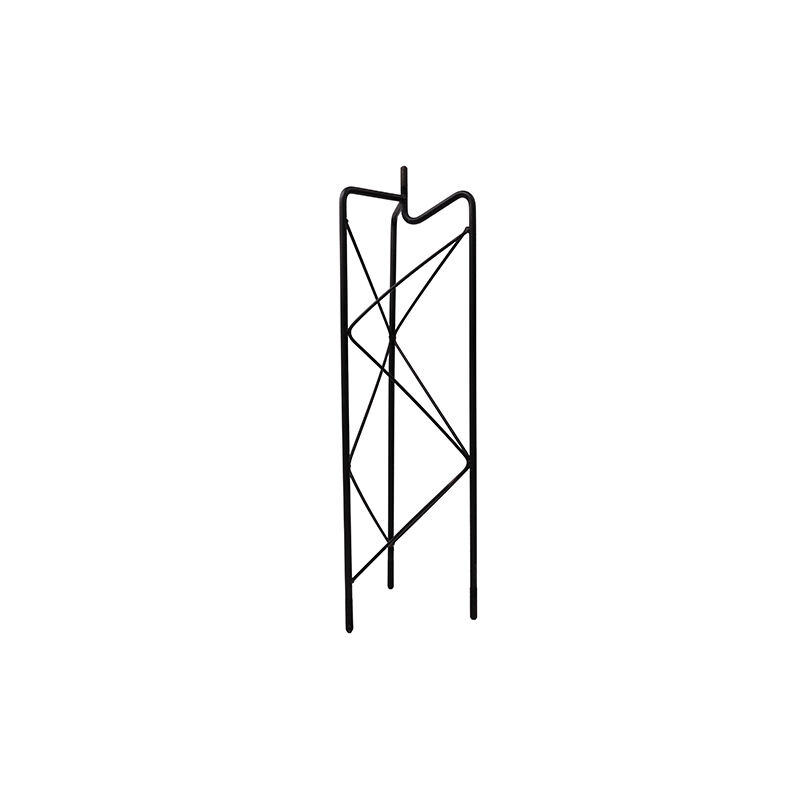

The bags are constructed from extremely tough material known as glassfibre. This stuff is seriously hard! It withstands high temperatures and corrosive chemicals without damage. This means that the bags can work for long time - very long than other kinds of bags. They are the factory cleaning superheroes!

One thing that can pollute the air in big factories are sick machines. There’s smoke and dust and little bits of everything in the air. These special glassfibre filter bags make sure that all those little fractions floating around get caught. They safeguard the workers and maintain the machines to be clean and well-functioning.

What makes these bags a really good deal for factories is that They're so powerful that factories don't buy new bags constantly. This saves factories money and we all know that is a good thing! These bags are like, something you purchase that has longevity, that performs, they perform.

These bags are like little special guards that help protect the workers. It catches little bits that may hurt people if they breathe them in, so clean air is really important when someone works in a factory. The bags are working overtime to ensure that people can breathe without difficulty and remain healthy.

The glassfibre filter bags from Hongshida are really great! They’re the superheroes of clean air. They clean the air, protect workers and help factories run more efficiently. These special bags perform an important task that helps keep people safe and healthy.

Our company has earned ISO9001 accreditation for our quality management system. This assures us that we can offer high-quality products and services in a reliable and consistent manner. We also focus on the principles of quality management which includes quality planning and control, quality assurance, and the improvement of quality. Our intention is to collaborate with our Glassfibre filter bags. We have a sophisticated testing system, a stringent management system, a top-quality assurance system, and a large production capacity to ensure that the high-quality of our products.

Our products are the largest of the market in this industry in China, and the raw materials we use are assured. Since the stamping parts are manufactured with molds, errors that could be caused by traditional processes are eliminated, and quality of the product is guaranteed. Based on the material used, the films may be applied to the product during manufacturing to stop Glassfibre filter bags. This set of procedures laid the foundation for the top-quality products of our company in addition to their favorable reception from our customers.

We have a Glassfibre filter bags after-sales team, for the product to reach the customers' needs, we offer various solutions to customers, in order to resolve their issues. Customers may have specific requirements for packaging when purchasing a product from us. Then, we will package the products according to their specifications. If, when the product is delivered to the customer, the product has been damaged due to transport, or its surface quality has scratches, etc. Our company offers an exchange or return service for free. Customers are more confident when purchasing our products and the re-purchase rate is quite high.

Glassfibre filter bags company has more than 2000 different types of items, with sizes and specifications which match with the majority of products available. Steel, stainless steel and other materials are used to make the products. Our company's products can adapt to various application fields and play an important role. Moreover, our company supports personalized products with mold making. The mold design and development team can make products custom-made based on sketch of the customer and then after discussion with our mold design team. Other accessories are also attached to existing items in the manner that is in line with customer specifications.