A Mesh is basically a special tube for measuring how fluids (liquids or gases) flow through it. Just picture a piece of tube but in a funnel shape. There is a small narrow region in this tube. As the fluid passes this constriction, it flows faster than it does in the larger sections of the tube. Since it's moving faster in that part, the pressure, or how hard the fluid pushes, decreases. This change in pressure can be used to determine the volume of fluid flowing through the tube. That is common in many jobs where being able to understand the flow of a liquid or gas is important.

The venturi tube was a brilliant creation of an Italian scientist, Giovanni Battista Venturi in the 1700s. He learnt how to use the laws of physics to construct this tube. A special law that will help us understand working principle of venturi tube is the Bernoulli equation. This rule basically says that when a fluid is moving fast, the pressure of that fluid goes down. The venturi tube is shaped very precisely to establish a desired pressure differential. This difference is what actually allows us to quantify the fluid flow. Without this design, getting the accurate measurements would be much more difficult.

The Venturi tube is featured in many sectors, often for critical functions. For example, they use venturi tubes to measure a batch of chemicals in chemical plants that are used to make a variety of chemicals. They also control and monitor water flow through tubes that are installed in water treatment plants, where they clean and treat water. Indeed, they also work in the oil and gas industries. There, they assist in acquiring extremely accurate measurements of the way gas and oil travel through pipes. Also in airplanes, where venturi tubes are important. They assist in regulating the speed of air movement during flight, which ensures safety and performance of the craft. While they may be filled with colors that seem like they're only used for fun, it's great that we can also see how frequently you use these tubes in your daily life.

Venturi tubes are good, but they have pitfalls. Venturi Tubes- The very first thing that a very top-class feature of the Venturi tube is that it gives a very very accurate measurement of the flow of fluids. It means they are a Source You Can Trust, a source of information people can trust. They are also very easy to install, and best of all, they don’t require any sort of power to operate. But there are limits to their use. They have a certain flow capacity, so they may not be the best for larger amounts of fluid. Uniformity of composition - ventilator tubes may additionally be much less correct if the fluid being measured includes little debris in it. Dirt or contamination in the fluid can also throw off the measurements.

Proper installation and maintenance are key to ensuring venturi tubes operate effectively. They have to line up the parts of the tube where the fluid flows in and out. Aligning the two helps ensure we measure the flow of the fluid accurately. It is also very important to keep the inside of the tube clean and smooth. Any dirt or rough spots at the inside may change the operating condition of the tube. If you take a moment to check and clean the tubes once in a month then it will surely enhance their working and performance accuracy. These steps are necessary to guarantee that the venturi tubes will continue to provide accurate measurements for many years.

Our company's products dominate the majority of the market of this industry in China and the raw materials we use are guarantee. The stamping parts, which use molds instead of venturi tube that are less prone to failure and are free of errors. When producing products, sometimes according to the nature of the material, the film is placed on the material to avoid defects or defects in the surfaces of the item. By this method has laid the foundation for the high quality of our products. The product is also very well-received by customers.

Our after-sales services are strong. We provide customers with a wide range of solutions to ensure that the product is able to venturi tube their needs. Customers might have particular specifications for packaging when they purchase an item from us. We then package the products according to their specifications. If when the product arrives to the customer, the product becomes damaged as a result of transport, or its product's surface has scratches and scratches, etc. Our company offers no-cost return and exchange services. So, buyers will feel more secure when purchasing products from our company, and the rate of re-purchase is extremely high.

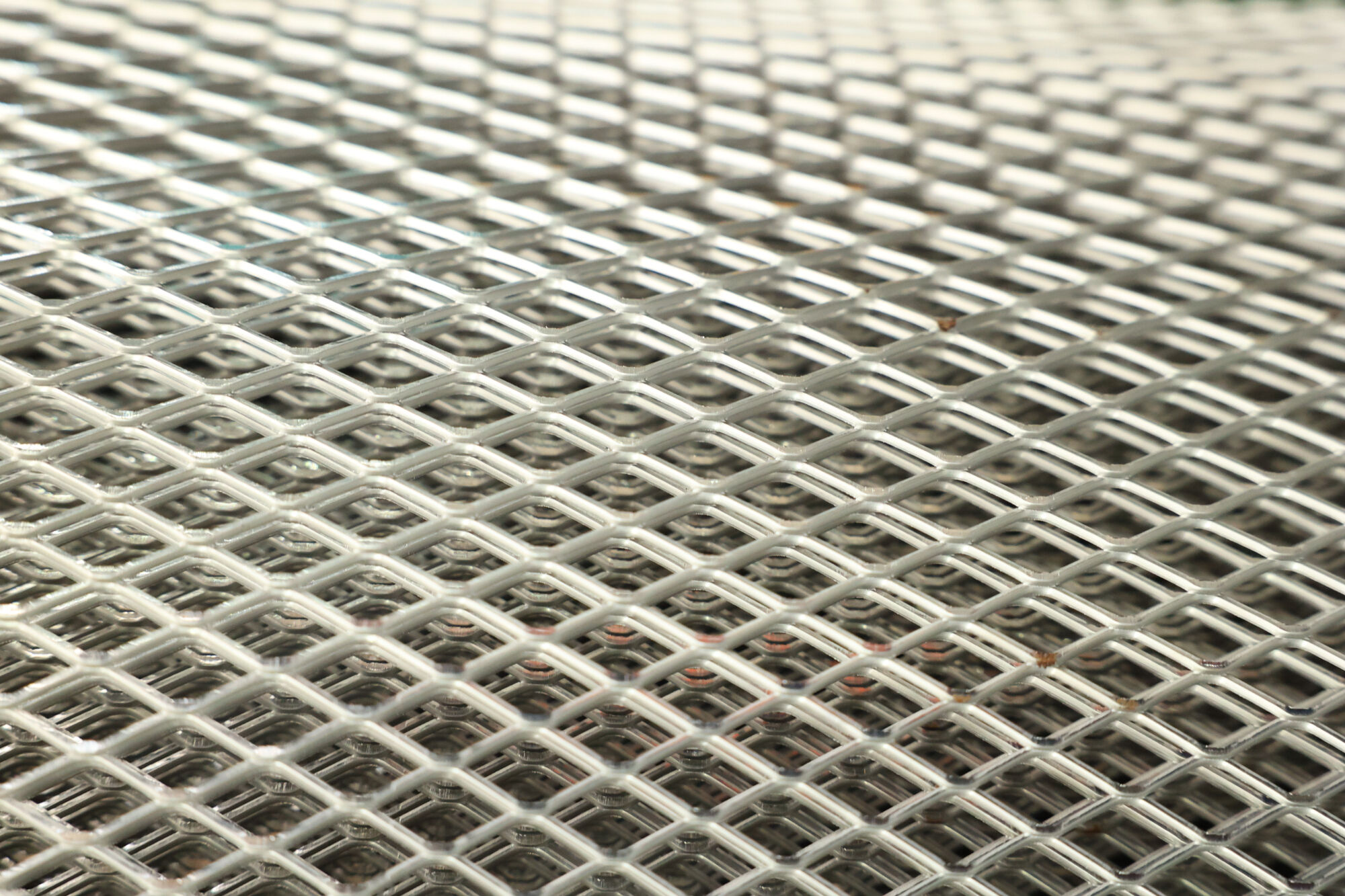

Our company offers more than 2000 kinds of venturi tube with specifications and sizes that match most of the products available. Our products are made of high quality, which includes stainless steel, iron, and more. The products we offer are able to be used in various applications, and have a major role to play. Additionally, we offer customized products through mold making. We have a highly skilled mold design and development team, which, based on customer drawings and then after discussion and design by the mold development team designs the products customers would like. Other accessories can also be added to existing products the manner that is in line with customer specifications.

Our company has passed the ISO9001 quality system certification to ensure we can provide continuous and quality products and services that are stable and reliable, emphasizing the principles and practices of quality management which includes quality planning, quality control quality assurance, and quality improvement. We have implemented this system to ensure the consistent quality of products and improve the satisfaction of customers. And the intention to cooperate with our company. We have an excellent quality assurance system, strict management system, strong venturi tube for production and the latest testing equipment, to guarantee that our products are with high-quality, huge production capacity at while, they also are competitive on the market.