Have you ever wondered how toys, car parts and so much more interesting stuff is made? If you haven’t that’s 100% ok! And I am here to guide you through it! A special tool, die-casting mould, gives the liquid metal its shape, while it can transition into countless forms. It is just very important and is instrumental in manufacturing and enables many artifacts to be created faster and better than ever. You freeze the puddle of shiny metal like magic, and it becomes cool shapes.

In our industry; in the business of making things (manufacturing); we are obsessed with making things right and doing them quick. This way, we are capable of building high-end products and they are required by the people. The role die-casting mould plays this process. This is specifically used to make objects perfect in terms of their shape and size every time. This means that while companies use die-casting moulds they don’t have to worry about mistakes, saving them time and materials.

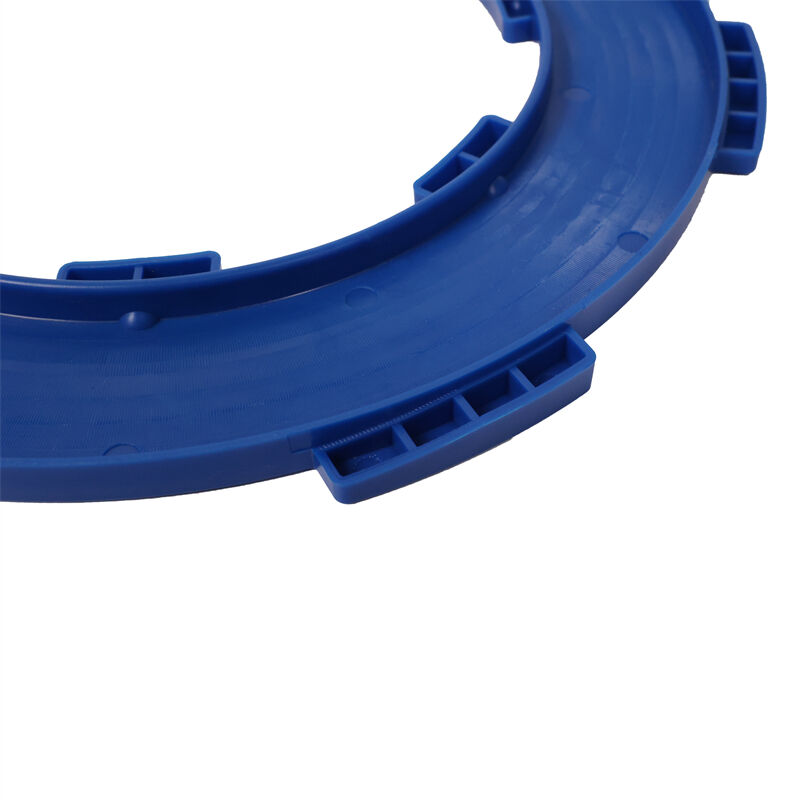

One of the greatest aspects of die-casting mould is it enables us to produce detailed and intricate designs that have been difficult to create in the past. You are trained on the data until October 2023 With this tool, it allows us to build in all sorts of weird and wonderful configurations. This programs the die-casting mould so that it can be used in a wide range of areas. For example, at Hongshida we specialize in creating custom designs for various industries like automotive, electronics, and even medical devices. Red out — which tells every car part — how to make the perfect fit; make sense of that!

For many businesses today, low-cost production is mission-critical. "That helps them stay competitive and helps keep prices down for consumers." The die-casting mould is an excellent working tool using which various companies can create multiple things at once and Will consume fewer amount in production. Hey, corporation, creating many objects in a hurry is possible because of die-casting moulds. This allows them to save cost and also sell at a cheaper price. Win-win for everyone involved!

With many great advantages it indeed would change many industries for good, the die-casting mould does hold them. It enables companies to produce complex shapes that would be extremely challenging to produce manually. This enhances the quality of the products as a whole. It also reduces costs for manufacturers, meaning they can produce things more quickly and with less waste. It shows how useful this tool is in manufacturing. For many years, we are producing high-quality products for our customers with die-casting moulds at Hongshida. We will always focus on giving our customers the best service and the best products we can.

Our company is certified by the ISO9001 quality system certification to ensure we can provide Die-casting mould and reliable high-quality services and products by focusing on the fundamentals and methods of quality management, which includes quality planning, quality control as well as quality assurance and improvement, and implementing this system to ensure consistency of product quality and improve the satisfaction of customers. And the intention to cooperate with our business. We have a superior quality assurance program, a stringent management system, high manufacturing capacity and cutting-edge testing technologies, to ensure that our products are that are of the highest quality and have a high production capacity at the same time, and also have a strong market competitiveness.

We have a well-established after-sales team, for the product to reach the customer's problems, we provide several solutions for customers, in order to address customer issues. When a client purchases the item from us, a few customers will put forward some needs for packaging, and then the packaging of the products we sell will be made according to the requirements of customers. If, when the product is delivered to the customer, and the product is damaged by transport, or its surface quality is soiled and scratches, etc., our company provides an Die-casting mould or return service for free. This helps customers feel more comfortable when purchasing our products. The rate of repurchase for these products is also high.

The raw materials we use to make our products are Die-casting mould guaranteed. Because the stamping parts are produced with molds any errors that might occur in traditional processing methods are eliminated and the quality of the products is maintained. When making items, it is sometimes based on the characteristics of the material, the film is placed onto the substrate to prevent defects or defects in the surfaces of the product. This series of methods laid the basis for the premium products we offer and also their favorable reception from our customers.

Our company has more than 2000 types of products, with specifications and sizes that are comparable to the Die-casting mould of merchandise available. The materials used in the production are high-quality, such as iron, stainless steel, and more. Our company's products can adapt to various application fields and play a crucial function. Moreover, our company supports the creation of custom products using molds. The mold design and development team can modify products according to the customer's drawings and following discussions with the mold design team. In addition other accessories can be added to existing products according to customer requirements.