So, if you want to learn about venturis, you are at the right place! Venturi flow tubes are special devices that are used to measure the flow of liquids and gases. They are essential in many sectors, especially ones that deal in liquids such as water, oil, and gas.

Factories and other places use venturi flow tubes to measure how fast liquids are moving. Think of a pipe that you push a fluid through. The pipe is called a venturi meter. There is a nice piece shaped inside this pipe. This section is referred to as the throat. Its diameter is narrower than that of the rest of the pipe. As the liquid passes through this narrow section, it must accelerate. This is kind of like how you squeeze a garden hose. Cover the end with your thumb and the water flows much more quickly.

As the liquid passes through the venturi meter, it accelerates while passing through the throat portion. It excites it, and this difference in speed causes a difference in pressure. That is to say, the pressure is lower at the narrow part of the pipe than the wider parts. A sensor can detect this change in pressure. This is a sensor that indicates how quickly the liquid is flowing. So we can tell the flow rate of the liquid by observing the pressure difference.

The venturi tube principle works based on the so-called Bernoulli effect. This is a scientific law that goes into the physics of fluid velocity and fluid pressure. By this rule, when the movement of the liquid increases, the pressure lowers. So, inside the throat of the venturi tube, the liquid flows faster, thereby causing the pressure to decrease. This principle explains why the venturi tube is so well suited to liquid flow measurement.

Venturi flow tubes are very precise at determining flow. They have several advantages. First, they have low maintenance needs, which means they are easy to take care of. Second, they can operate successfully in a wide variety of temperatures and pressures, which makes them extremely versatile. Third, they have no moving parts that can fail or wear out. This enables them to withstand the test of time without the need to be made new again, which is good for businesses.

Though venturi flow tubes prove to be very practical, they come with certain limitations. For instance, the flow of the liquid can be too fast or too slow and therefore lead to inaccurate measurements. However, with a venturi flow tube, a few critical factors come into play that will give you optimal results. These include:

The raw materials that we utilize to create our products are guaranteed. The stamping parts, that are produced using molds rather than traditional methods which are more durable and free from errors. In the manufacture of products, sometimes according to the nature of the material, the film is placed on the surface of the material to avoid problems or defects that may occur in the surfaces of the item. This method set the foundation for the high-quality products that we venturi flow tube and the positive reviews from customers.

We have a seasoned after-sales team, for the product to address customers' requirements, we provide a variety of solutions to customers, to solve customer problems. Customers might have venturi flow tube packaging requests when they buy the product from us. We then pack products in accordance with their specifications. Our company offers a no-cost exchange and return service in case the product is damaged during transportation or has been scratched. Customers can be more confident in purchasing our products. Repurchase rates for these items is also high.

Our company is certified by the ISO9001 quality system certification to ensure we can provide venturi flow tube and reliable high-quality services and products by focusing on the fundamentals and methods of quality management, which includes quality planning, quality control as well as quality assurance and improvement, and implementing this system to ensure consistency of product quality and improve the satisfaction of customers. And the intention to cooperate with our business. We have a superior quality assurance program, a stringent management system, high manufacturing capacity and cutting-edge testing technologies, to ensure that our products are that are of the highest quality and have a high production capacity at the same time, and also have a strong market competitiveness.

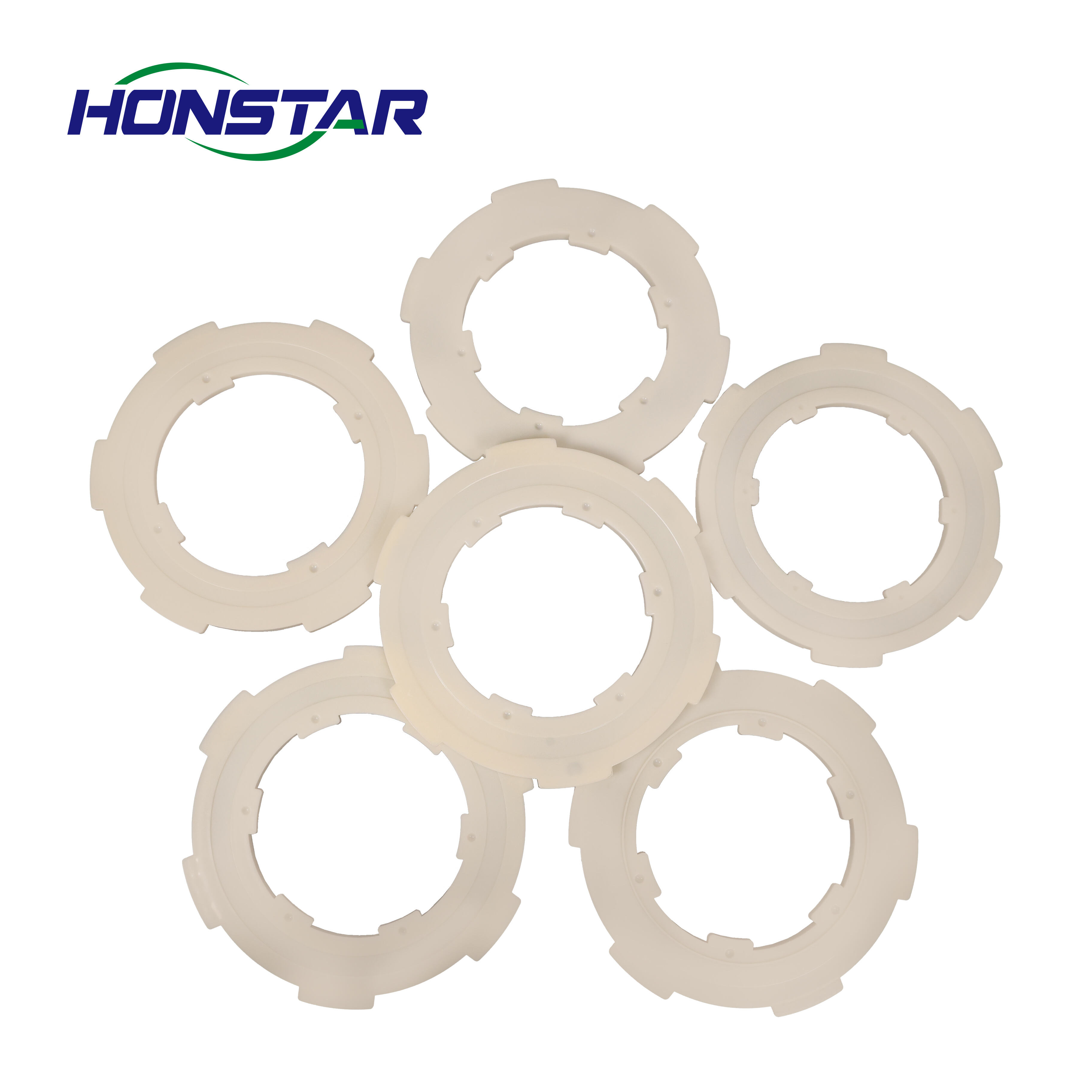

Our company stocks more than 2000 varieties of products with specifications and sizes which match with the majority of items available. The materials used in the production are high-quality, such as venturi flow tube, stainless steel, and much more. Our company's products can adapt to various application fields and play an essential function. Our company also offers customized products through the use of molds. We have a seasoned mold development and design team, which, based on the specifications of the customer's drawing and following discussion and design by our mold development team creates the products customers would like. While at the same time other accessories are able to be attached to existing products according to customers' specifications.