You know what PET spunbonded Filtration nonwoven is? It is a unique type of material that is formed by interlacing strings or cables. In this process a tight and useful fabric is formed that serves many intents. So, now that you know a little about woven mesh, why it is interesting and useful in our everyday lives? We will learn everything there is to know about woven mesh: the benefits of woven mesh, where we use it, how we make it, and how to decide which woven mesh is right for your needs in this text.

Woven mesh is a very strong and solid material. It can be made from various metals, plastics, or other types of fibers. The versatility of woven mesh allows for a myriad of uses. You could see it in buildings, in artworks or even household items. This material is unique in that it is malleable and open for creative use, which makes it a popular choice for builders and artists alike.

The strength of woven mesh is one of the main reasons it is so useful. It wont break or tear under a lot of weight, so is ideal for heavy duty jobs Woven mesh serves as a construction material and provides support and safety to various structures. Another feature of woven mesh is its great flexibility, as it can be easily bent and shaped to different sizes and forms. It is due to this versatility that woven mesh can be used for a vast number of projects. One more attribute of woven mesh is that it is permeable to air. Very useful for filters and screens that need to allow air to pass, keeping other things out.

Woven mesh is lots of common and has several wide applications. In the construction industry, it is widely used to strengthen concrete, thus leading to safer and more reliable buildings and structures. Safety secures woven mesh is frequently fabricated to shield where development is being completed. Woven mesh is used in the automotive industry for making airbags and seatbelts that are meant to provide safety to individuals in a vehicle. From filtration to separation processes, woven mesh finds immense purpose in factories and industrial processes as many of such processes rely on separating the materials present. Lastly, arts and crafts is a popular service area for woven mesh, as subsequently, this material can be used to create beautiful and strong items such as jewelry and clothing!

It is a homemade craft that has been done for decades. It is made by weaving threads or wires together to create the mesh fabric. Haand one which gives you the option of doing a better task and being accurate, the moment we talk about machines they provide us in large quantity but with out any lag. Whichever method is used, woven mesh requires skill, patience and careful working. With the human skill set in weaving heightening, designs blended together work making different patterns, tone shields using this adaptable material.

Choosing the right woven mesh for your project is crucial, and there are several factors to consider before making a selection First and foremost you need to consider material, its size, strength etc. All of these will affect how suitable the woven mesh will be for your application. If you need a strong mesh to use for construction, then you should know that a metal one will be a strong option. If you’re making something lighter-weight, a synthetic or plastic mesh may be a better match.

One high-quality woven mesh product is the Hongshida brand. They come in metal, plastic, and synthetic mesh varieties as well. Hongshida is trusted by many, and their woven mesh is powerful and strong, so it's more robust for tough jobs. You know you can always trust them to make what you want.

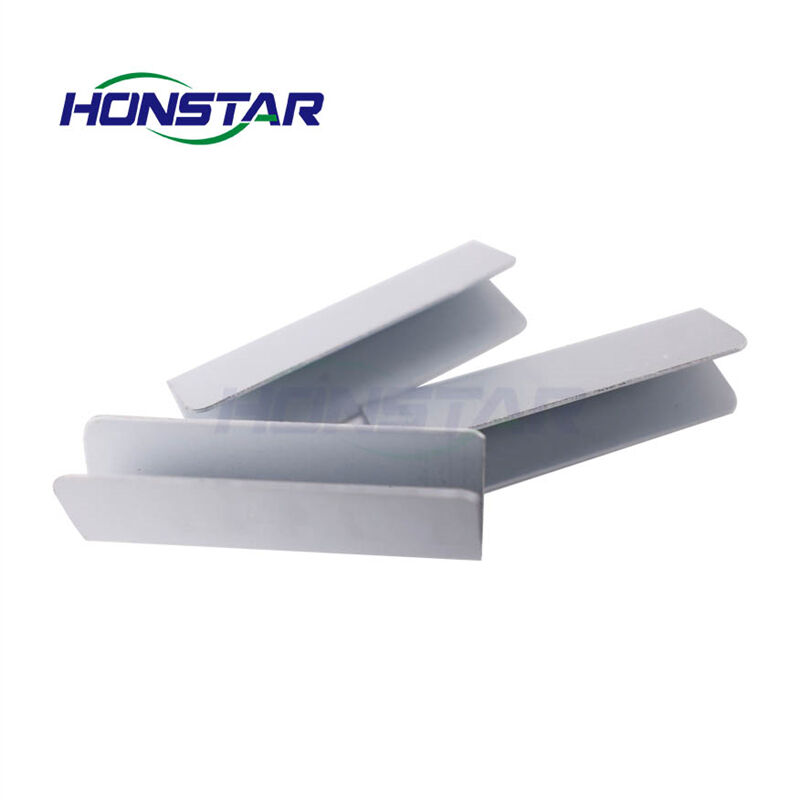

woven mesh company's products dominate the majority of the market share of this sector in China and the raw materials we employ are assured. The stamping parts, that use molds, instead of the traditional method they are more reliable and free from mistakes. In the production of products, sometimes according to the characteristics of the material, the film is placed on the material to avoid imperfections or flaws in the surfaces of the item. By this method established the basis of the excellent quality of our company's products, but also very well-received by customers.

Our company has been awarded ISO9001 certification for its woven mesh. This assures us that we can deliver high-quality services and products in a reliable and consistent manner. We also focus on the importance of quality management such as quality planning and monitoring as well as quality assurance and quality improvement. We are looking forward to working with our business. We have an advanced testing system, a strict management system, a top-quality assurance system, and a large production capacity to ensure that our products' high quality.

We woven mesh over 2000 types of products with dimensions and specifications which are like the majority of products available. Steel, stainless steel and other materials are used to create the products. Our products are adaptable to various application fields and play a crucial role. Furthermore, our company offers custom-designed products by using molds. Our mold design and development team is able to customize products based on the sketch of the customer and then after discussion with the mold design team. While at the same time additional accessories can be welded on existing products based on the specifications of the customers.

woven mesh have a strong after-sales department, to help our products to be able to resolve customer's problems, we provide a variety of solutions to customers, in order to resolve their issues. When a buyer purchases a product from us, some customers may submit specific packaging requirements. The packaging of our products is done in accordance to the specifications of the customers. If the product is transported to the customer, the product becomes damaged as a result of transportation, or the surface is damaged, etc., our company provides an exchange or return service for free. Customers can feel more confident when buying our products. The repurchase rate of these products is also high.