Mesh is a really incredible type of fabric in the world of fabrics and most of the people may not know about this. We, Hongshida brand, are so pleased to show how stunning and functional twilled weave mesh is! It is not like any other clothing or product material and has special qualities that make it different from the rest.

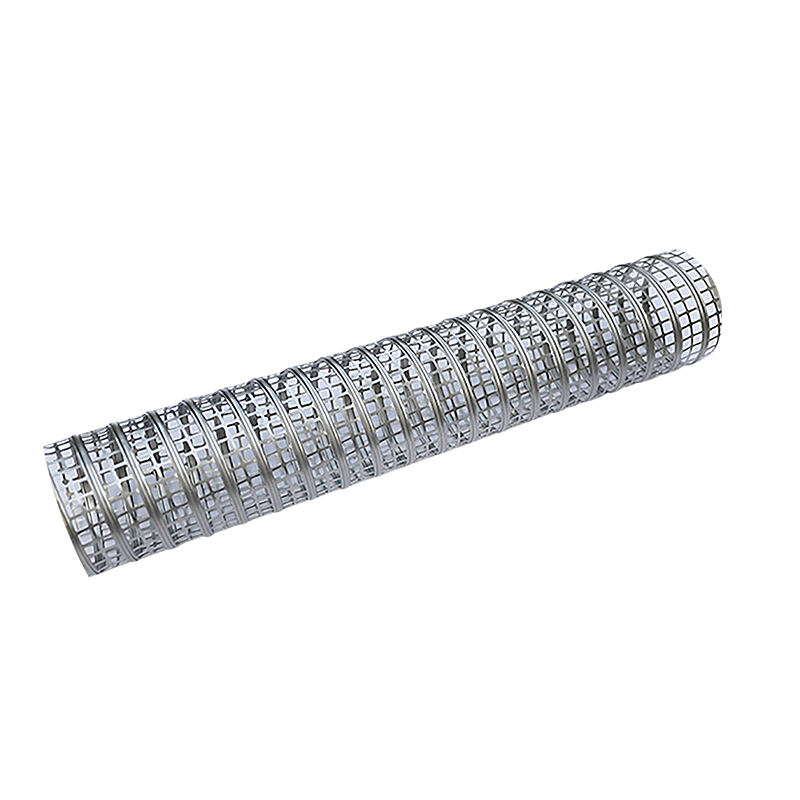

Another fabric named twilled weave mesh, produced with a specific type of weaving. This is a different way than most fabrics deriviq from. This makes the surface of the cloth have diagonal lines and bumps on them which makes it look quite pretty and unique. Twilled weave mesh is unique in that the threads are woven together to create a very strong and durable fabric. Because twilled weave mesh fabric has greater resistance to damage, this means the items made of this type of mesh can withstand far more and resist the effects of wear and tear better than many other types of fabric. It’s like a superhero cape but like where you can wear it and still look good and also being protected!

One of them is the twilled weave mesh, which has some cool qualities that make it perfect for a lot of different projects. It’s also, for one, light, so it doesn’t feel like you are wearing cement. It also has some stretch, and allows for decent airflow. That is why it is great for sewing clothes such as shirts, jackets, and pants. Think wearing a shirt so soft and your skin can breathe—this is the mesh system of a twilled weave!

In addition, this fabric is extremely durable and virtually tear proof, which is why it has been widely used for items such as bags, outdoor equipment, and furniture covers. So, for instance, a backpack with a twilled weave mesh can hold your books, supplies etc without tearing easily. The manufacturing process of twilled weave mesh makes it excellent for varied applications, hence the high demand.

Twilled weave mesh has existed for a quite number of time. It is not a new invention! It has been used since ancient times for clothing and other textiles. Back in the early days twilled weave mesh was essential in creating durable clothing to wear. Our method of producing twilled weave mesh has changed a lot over the years. Today there are special machines to help produce a variety of twilled weave mesh fabrics with beautiful patterns and designs that were previously unavailable. In other words, it lets you own the twenties twilled weave mesh fairy tale and the silky starlight modern fairy tales.

This twilled weave mesh has a multitude of uses today, and can be found in everything from. Its influence is visible in clothes, cars and even factories. In cars, for separation, it is used in airbags and seat covers due to great strength and durability. And it aides in keeping us safe as we travel. For example, in the construction industry, twilled weave mesh provides better strength in the concrete and prevents soil from being washed away by heavy rains. That is vital to construct secure and freestanding structures.

Twill weave mesh comes in many different patterns, and each has its own unique appearance and function. Some general patterns are herringbone, diagonal, and zig-zag. The result of all this seeming origami is the herringbone pattern, which resembles a V in shape because of the way the threads are woven together. This kind of design is made by slanting lines and having diagonal lines in between. Kite: The kite stitch has threads that go back and forth while creating the crafty kite look. Patterns of these can be used to build all kinds of fabrics for different purposes giving choice and flair.

Our after-sales services are strong. We provide customers with a wide range of solutions to ensure that the product is able to solve the issues they face. When a buyer purchases a item from us, a few customers may submit packaging requirements, then the packaging of our products will be done in accordance with the needs of customers. Our company offers a free return and exchange service in the event that the product is damaged during transport or has a scratched surface. This allows customers to be more Twilled weave mesh in purchasing our products. The repurchase rate of these products is also high.

Our company's products dominate the majority of the market of this industry in China and the raw materials we use are guarantee. The stamping parts, which use molds instead of Twilled weave mesh that are less prone to failure and are free of errors. When producing products, sometimes according to the nature of the material, the film is placed on the material to avoid defects or defects in the surfaces of the item. By this method has laid the foundation for the high quality of our products. The product is also very well-received by customers.

Our company is certified by the ISO9001 quality system certification to ensure we can provide Twilled weave mesh and reliable high-quality services and products by focusing on the fundamentals and methods of quality management, which includes quality planning, quality control as well as quality assurance and improvement, and implementing this system to ensure consistency of product quality and improve the satisfaction of customers. And the intention to cooperate with our business. We have a superior quality assurance program, a stringent management system, high manufacturing capacity and cutting-edge testing technologies, to ensure that our products are that are of the highest quality and have a high production capacity at the same time, and also have a strong market competitiveness.

Our company offers more than 2000 different types of items, with specifications and sizes that match most of the products available. Steel, stainless steel and other substances are used in the production of the products. Our products can be adapted to a variety of applications and Twilled weave mesh a significant part. Our company also assists customers in creating custom products using molds. Our mold design and development team is able to modify products according to the customer's drawings and following discussions with the mold design team. In addition other accessories are able to be welded onto existing products based on the requirements of the customer.