Have you ever wondered how factories and power plants keep their air clean and safe? For this process, one key tool is a Mesh. The mesh demister is a special device for liquid removal from gas. It does this with a screen or pad that serves as a filter. This filter filters out the liquids, allowing only clean gas to escape. When it comes to maintaining our environment, mesh demisters are essential in ensuring that only clean air enters the environment.

For factories, A mesh demister gives a lot of advantage to enhance their procedure. If a gas stream has too much moisture or liquid, it can block pipes and machines. When that occurs, it can cause air quality to suffer and also lead to machine failure. This is bad for the factory because it can waste time and money. This allows factories to maintain clean and transparent gas flow using the mesh demister, which improves the operation of the equipment. As a result, the factory can practice without downtime, both saving time and money.

The metal mesh also creates the best airflow and quality air in any industrial units. Backing up the gas stream with liquids can slow or stop machines; a mesh demister removes the liquids. This is important because when machines run smoothly, the entire factory runs smooth. A mesh demister also cleans the air further, filtering the air contaminants from the working atmosphere that may cause harmful workers. It is our hope that by building and creating a safer work environment, employees will treat and perform their jobs without the fear of jeopardizing their health.

A mesh demister is excellent at separating liquid from gas, as we've previously said. This separation is critical because blending liquids with gases can be very troublesome. For example, in power plants, big steam-powered turbines rotate to create electricity. If small water droplets of steam are mixed with the stream of gas, it can cause serious problems. The water could cause damage to the turbines, and in some instances it could spark a fire. Using a mesh demister in these types of factories can prevent such dangerous conditions from occurring, thus saving both the equipment and the employees.

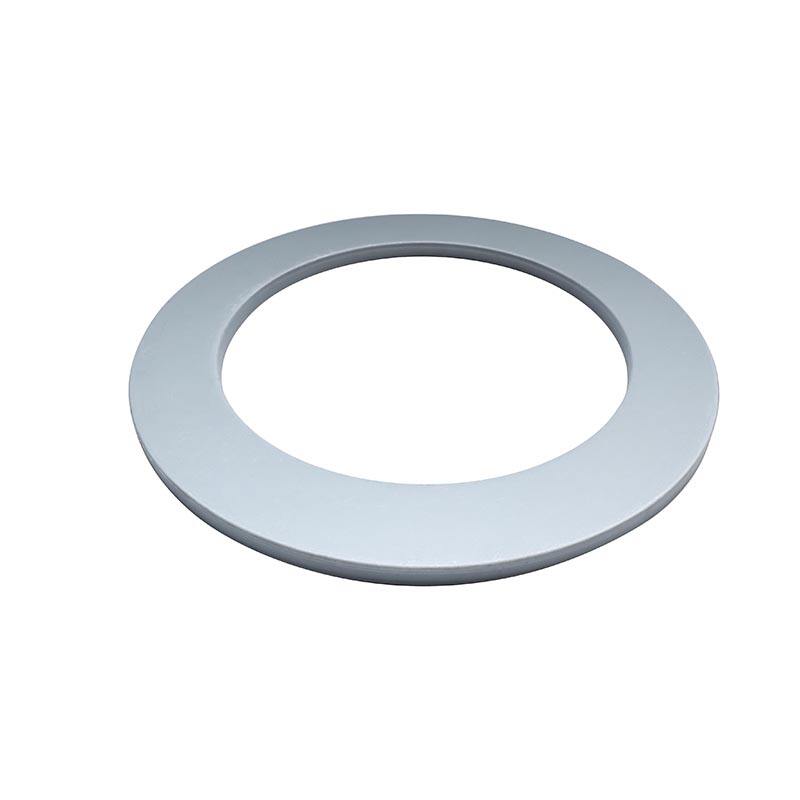

There are a few critical considerations to make when selecting and installing a mesh demister. For one, you need to determine what size demister you will require. This size depends on the size of the gas stream in your facility. Some demisters are simply too small for a drip tray, and if the demister is too small, it will fail to function. Also, consider what kind of mesh demister you require. There are many types, namely, chevron, vane and knitted wire with each unique application. Finally, the demister needs to be installed in the right position. Where that device is placed relative to the plant piping is important to achieving good features of it, such as liquid removal from the gas stream.

V.,04634912 (up 3. We realize that every factory and industrial plant is unique, which is why we offer tailor-made solutions that will best suit your requirements. Our specialists assist you through the selection process and installation of the appropriate demister. Let us help you stay on top of your factory, and keep everyone safe in the workplace.

Our company has earned ISO9001 accreditation for our quality management system. This means that we're able offer top-quality products and services in a reliable and consistent way. We also insist on the fundamentals of quality management which includes quality planning and control, quality assurance, and the improvement of quality. The intention to work with us. We have a sophisticated testing process, a mesh demister management process, a high-quality assurance system, and a large production capability to ensure our products' high quality.

We have a mesh demister after-sales team, for the product to reach the customers' needs, we offer various solutions to customers, in order to resolve their issues. Customers may have specific requirements for packaging when purchasing a product from us. Then, we will package the products according to their specifications. If, when the product is delivered to the customer, the product has been damaged due to transport, or its surface quality has scratches, etc. Our company offers an exchange or return service for free. Customers are more confident when purchasing our products and the re-purchase rate is quite high.

Our company has over 2000 different types of items, with mesh demister and sizes that match most of the products on the market. Our products are made top-quality, including stainless steel, iron and many others. Our products are able to adapt to different fields of application and play an important role. Our company also offers customized products by using molds. The mold design and development staff can create products that are customized based on the sketch of the customer and then after discussion with our mold design team. At the same time additional accessories can be attached to existing products in accordance with customers' specifications.

Our company's products dominate the majority of the market of this industry in China and the raw materials we use are guarantee. The stamping parts, which use molds instead of mesh demister that are less prone to failure and are free of errors. When producing products, sometimes according to the nature of the material, the film is placed on the material to avoid defects or defects in the surfaces of the item. By this method has laid the foundation for the high quality of our products. The product is also very well-received by customers.