Of course, plastic is an awesome material and can be just about anything we want! Plastic is everywhere around us, from the toys we play with to components inside of cars. It used to be very hard to make plastic things, but we've got this super bitching cool process we call injection molding that makes plastic creation relatively easy.

Now, lets think you have a very special machine that can heat plastic to melt it and you can pour it into a shape just like pouring juice into a cup. And that’s essentially what injection molding does! Here’s the abracadabra step-by-step:

The most awesome thing, though, is that it was able to produce thousands of plastic parts in a matter of minutes! Consider how long it would take a human to produce that many things with their hands. custom injection moldinging allows all that work to be done rapidly and with precision by one machine.

Fifty years ago, people would have to laboriously create plastic items, one at a time, for each individual by hand. And sometimes plastic parts would not look identical. Now, with injection molding, all the plastic parts are identical. It's like a great copy machine, that make copies again and again!

Injection molding is the process that allows us to manufacture so many products we use every single day. Whether its the plastic spoon you might use at lunch or the parts inside your parents' computer, it is amazing how common this process is!

Our company is certified by the ISO9001 quality system certification to ensure we can provide Injection mold and reliable high-quality services and products by focusing on the fundamentals and methods of quality management, which includes quality planning, quality control as well as quality assurance and improvement, and implementing this system to ensure consistency of product quality and improve the satisfaction of customers. And the intention to cooperate with our business. We have a superior quality assurance program, a stringent management system, high manufacturing capacity and cutting-edge testing technologies, to ensure that our products are that are of the highest quality and have a high production capacity at the same time, and also have a strong market competitiveness.

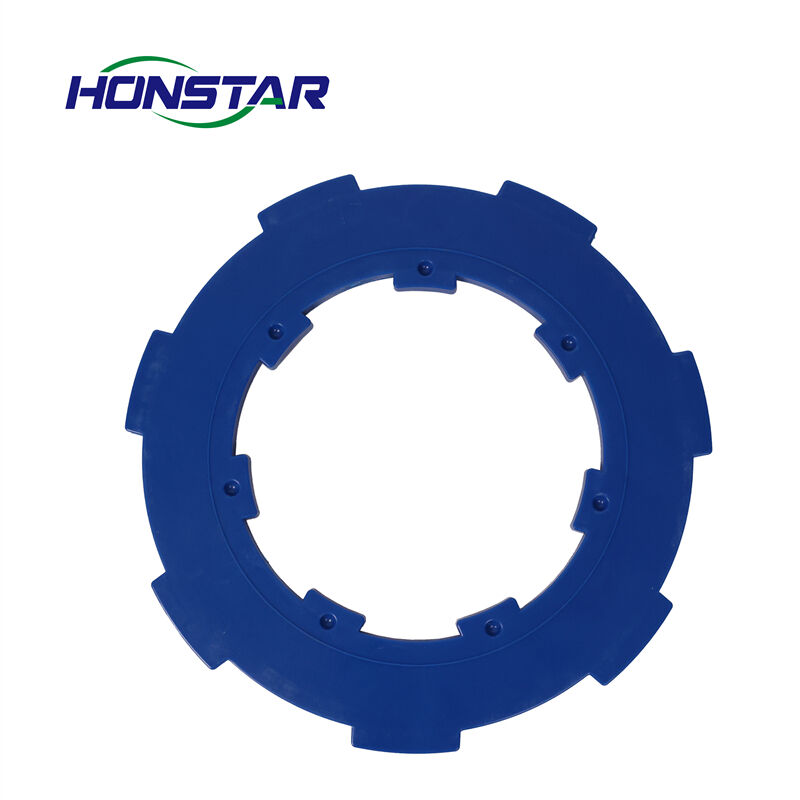

Our company stocks more than 2000 varieties of products with specifications and sizes which match with the majority of items available. The materials used in the production are high-quality, such as Injection mold, stainless steel, and much more. Our company's products can adapt to various application fields and play an essential function. Our company also offers customized products through the use of molds. We have a seasoned mold development and design team, which, based on the specifications of the customer's drawing and following discussion and design by our mold development team creates the products customers would like. While at the same time other accessories are able to be attached to existing products according to customers' specifications.

The raw materials we use to make our products are Injection mold guaranteed. Because the stamping parts are produced with molds any errors that might occur in traditional processing methods are eliminated and the quality of the products is maintained. When making items, it is sometimes based on the characteristics of the material, the film is placed onto the substrate to prevent defects or defects in the surfaces of the product. This series of methods laid the basis for the premium products we offer and also their favorable reception from our customers.

We have a seasoned after-sales team, for the product to address customers' requirements, we provide a variety of solutions to customers, to solve customer problems. Customers might have Injection mold packaging requests when they buy the product from us. We then pack products in accordance with their specifications. Our company offers a no-cost exchange and return service in case the product is damaged during transportation or has been scratched. Customers can be more confident in purchasing our products. Repurchase rates for these items is also high.