Hongshida is a manufacturer of special tools called called compression casting mold. How long is data is trained on these molds are extremely critical factors in producing proprietary brands of metal using heat and pressure and transfer molds. It is commonly used by the metalworking industry, where they process metals in the form of parts, but, in fact, it is not just about metals. Casting molds – compression casting molds are also used for making objects from plastics and other materials.

So, how [i]thing and process[/i] happens, is curious. First, the shaping material is heated until it is soft and even liquid. The material is then poured into the mold once it gets to the proper temperature. The mold is tightly pressed together, and the liquid that has been cast flows in to form the product. This is very helpful way as it allows manufacturers to make multiple items in one process, also called mass production. It is capable of producing numerous shapes from simple to complex which is where its versatility lies and finds many industries behind it.

The compression casting molds are a very good option for making products due to various reasons. But one of their biggest advantages is the ease with which they can be replicated, allowing them to create a large volume of products quickly and easily. They can generate extremely complex and intricate geometries, which is not something all manufacturing processes offer. This helps in industries that require producing large parts, such as the automotive and aerospace industries making it extremely useful.

Undoubtedly, when it comes to precision casting parts, for your casting production, you need to choose the right compression casting mold. Before you do that however, you need to consider what material that you will work with. We need different types of moles depending on the different materials like metals or plastics. To achieve the best results, you should choose a mold that is specifically designed for the material you want to work with.

Then, you are to choose the shape you want to work upon. Types of Molds in Moulding Some molds can only create basic shapes, whilst other molds can handle more detailed and complex shapes. Mold selection is all about understanding what you need. Also consider the number of pieces you would like to make. However, if you are planning to make a whole bunch of items, you may want a certain mold that can accommodate the audience. Finally, reflect on how urgently you require the production to be completed. Some molds may not have as fast of a turnaround as others, so be sure to pick a mold that will work with your schedule.

The configuration of a compression mould is critical for ensuring the quality of the end product. The first thing that you need to consider is what to use for the mold itself. This will be subject to high pressure at high temperature during the compression casting itself as such the material has to withstand considerable mechanical stress. This also means that the mold does not crack or get damaged by the products you are making.

The design of the mold itself is also crucial. It is something you should do with the end product in mind. However, obtaining optimal results requires a mold with suitable gateways called gating and venting systems. These openings are essential to controlling the material flow into and out of the mold during manufacturing to ensure the final product is constructed as desired. It can improve the quality of the products you manufacture if you have a good mold designed.

The Compression Casting Mold we use for the production of our products are guarantee-worthy. Since the stamping parts are produced using molds errors that could be caused by traditional processes are eliminated, and the product quality is stable. In the production of products, a lot of times based on the nature of the material, the film is placed on the material to avoid problems or defects that may occur on the surface of the product. This sequence of steps laid the foundations for the high-quality products that we manufacture, as well as their acclamation by our customers.

We have a seasoned after-sales team, for the product to address customers' requirements, we provide a variety of solutions to customers, to solve customer problems. Customers might have Compression Casting Mold packaging requests when they buy the product from us. We then pack products in accordance with their specifications. Our company offers a no-cost exchange and return service in case the product is damaged during transportation or has been scratched. Customers can be more confident in purchasing our products. Repurchase rates for these items is also high.

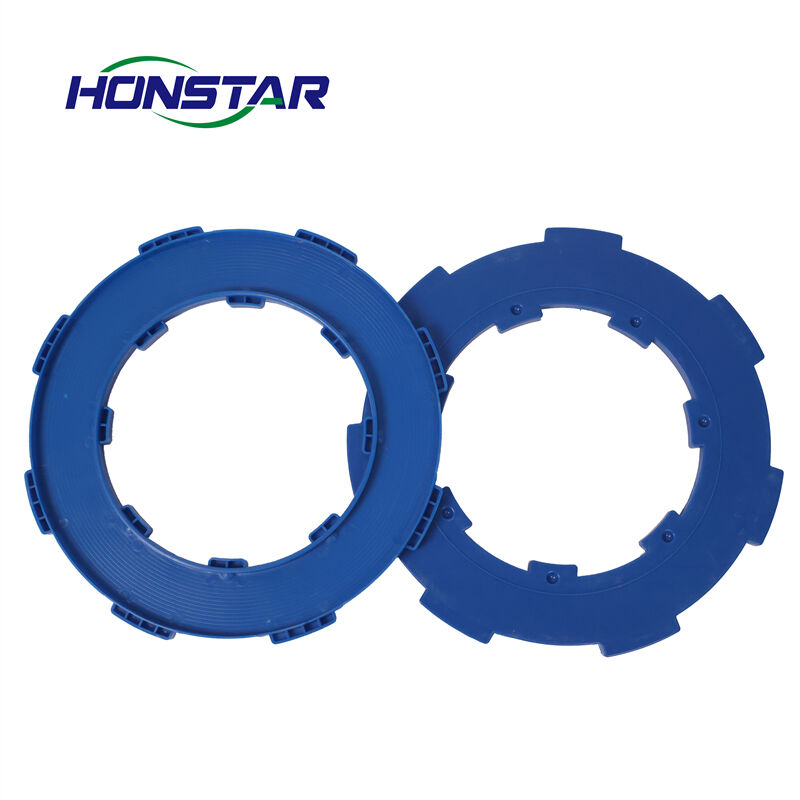

Our company offers more than 2000 kinds of Compression Casting Mold with specifications and sizes that match most of the products available. Our products are made of high quality, which includes stainless steel, iron, and more. The products we offer are able to be used in various applications, and have a major role to play. Additionally, we offer customized products through mold making. We have a highly skilled mold design and development team, which, based on customer drawings and then after discussion and design by the mold development team designs the products customers would like. Other accessories can also be added to existing products the manner that is in line with customer specifications.

Our company is certified by the Compression Casting Mold quality certification system to ensure that we are able to offer continuous and stable high-quality products and services by focusing on the fundamentals and methods of quality management, including quality planning, quality control as well as quality assurance and improvement, and implementing this system to guarantee the constant quality of the product and enhance the satisfaction of customers. and the intent to collaborate with our company. We have a superior quality control system, a rigorous management, powerful production capacity and advanced testing technologies, to guarantee that our products are of high quality, huge production capacity at same time, and also are competitive on the market.