Consider using Mesh if you are seeking a durable and robust mesh that can be utilized for multiple applications. This mesh is made from a special type of stainless steel which does not rust easily. It is resistant to rugged weather elements such as rain, snow, and heat. This is why it can stay relevant for decades and very rarely needs to be repaired or replaced. As a result, it is the perfect material for various construction applications that require long-lasting materials.

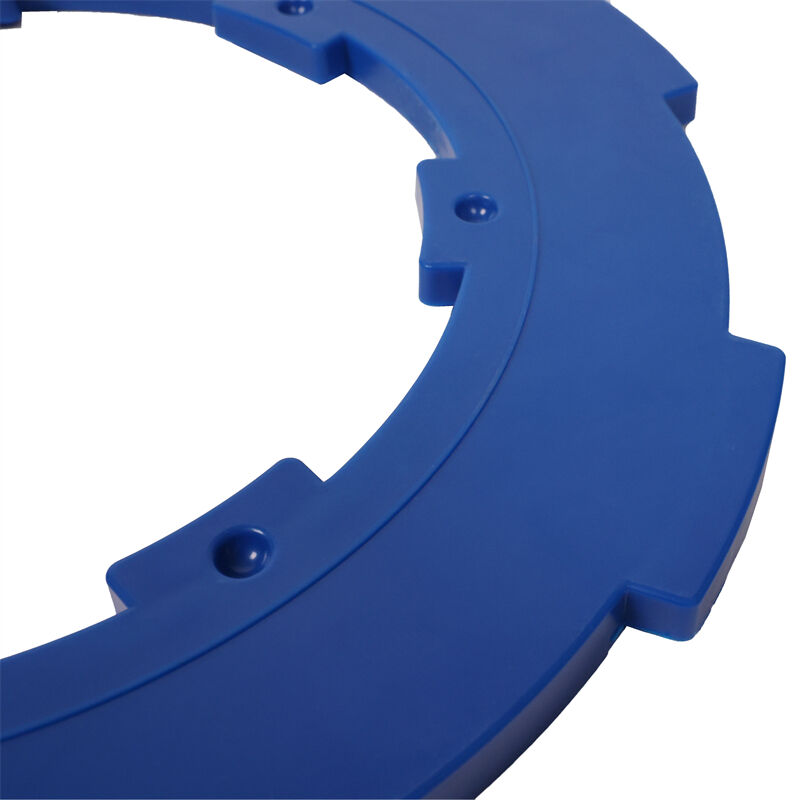

Stainless perforated mesh is a type of mesh with many small holes. SMEs often make these holes in various shapes and sizes, depending on the end use of the mesh. If you make some holes then they may be as small as pinholes while others holes can be bigger and all can be made according to needs. The size of holes can vary depending what you are attempting with the mesh. The versatility of data processing makes it a handy tool to carry out multiple tasks.

When compared to other mesh types, stainless perforated mesh offers several important benefits. Its primary advantage is its ability to last. The mesh itself is made from quality stainless steel, allowing it to resist tough conditions without becoming easily damaged. It also doesn’t rust, so it will remain in good shape for a long time. It is very easy to clean, and this is another advantage. This hardwearing material makes it an intelligent choice for high clean areas such as kitchens or factories where hygiene is imperative.

The versatility is another great benefit of stainless perforated mesh. It can serve a plethora of purpose and can work in various useful ways. For example, it is useful to filter or liquid and gases and keep on undesirable waste particles. It can also be in the ventilation to provide airflow while preventing larger objects. Furthermore, it acts like a barricade for fragile machinery, protecting them from the harm of outer forces. In addition to all of that, stainless perforated mesh can also serve a decorative purpose, adding an elegant appearance to buildings or furniture. That makes it an incredibly convenient material to use in just about any project.

Filtration: Filter media made from perforated stainless steel screening is often used in systems that filter liquids or gases. It aids in the elimination of dirt, sand, or other impurities, resulting in a cleaner and safer finished product.

Referred to as the “go-to material for many modular designs” stainless steel perforated mesh has a few distinctive qualities that help make it a great selection for a range of applications. Summary of mesh features of this type:

Corrosion Resistance: The durability of stainless perforated mesh is one of its most excellent qualities as it is highly rust-resistant. Because it can be used in rugged conditions like outdoors or kitchens and not have a concern about it getting damaged.

Our company is certified by the stainless perforated mesh quality certification system to ensure that we are able to offer continuous and stable high-quality products and services by focusing on the fundamentals and methods of quality management, including quality planning, quality control as well as quality assurance and improvement, and implementing this system to guarantee the constant quality of the product and enhance the satisfaction of customers. and the intent to collaborate with our company. We have a superior quality control system, a rigorous management, powerful production capacity and advanced testing technologies, to guarantee that our products are of high quality, huge production capacity at same time, and also are competitive on the market.

Our company stocks more than 2000 varieties of products with specifications and sizes which match with the majority of items available. The materials used in the production are high-quality, such as stainless perforated mesh, stainless steel, and much more. Our company's products can adapt to various application fields and play an essential function. Our company also offers customized products through the use of molds. We have a seasoned mold development and design team, which, based on the specifications of the customer's drawing and following discussion and design by our mold development team creates the products customers would like. While at the same time other accessories are able to be attached to existing products according to customers' specifications.

We have a seasoned after-sales department, to help our products to be able to stainless perforated mesh customer's needs, we provide numerous solutions for customers, in order to resolve their issues. Customers might have specific packaging requests when they buy an item from us. We will then package the items according to the specifications. If, when the product is delivered to the buyer, and the product is damaged by transportation, or the surface quality is soiled, etc. Our company offers an exchange or return service for free. Customers are able to feel more comfortable when buying our products. The repurchase rate of the products is also very high.

Our company's products dominate the majority of the market of this industry in China and the raw materials we use are guarantee. The stamping parts, which use molds instead of stainless perforated mesh that are less prone to failure and are free of errors. When producing products, sometimes according to the nature of the material, the film is placed on the material to avoid defects or defects in the surfaces of the item. By this method has laid the foundation for the high quality of our products. The product is also very well-received by customers.