There are many ways to do metal casting, when we want to shape objects from metal. A primacy process is the dies casting with the pressure. This is a common process used in metal work when detail and accuracy is important, such as factory processes. It is indeed a process that benefits manufacturers in producing products of high quality in an efficient manner.

The first step in the Mesh process is to heat metal to the point where it melts. Metal can be heated to a high temperature and become liquid. Once the metal has been melted the next step is to inject it into a mold. The mold is a hollow cavity of metal that gives the shape of the final product. Molten metal is injected into this mold under high pressure. This high pressure is crucial because it guarantees that the liquid metal completely fills it. The molten metal is poured into the mold, where it cools and begins to harden. It cools into the exact shape of the mold, resulting in an even final product.

One of the biggest benefits that pressure casting die gives you is an extremely accurate and precise product. The molds can have tons of tiny details, aiding in producing items that look exactly the way desired. How carefully the metal is injected means that even tiny pieces are reproduced well when the items are made. Another reason why this method is really common in factories or industries that have a high demand to produce a lot of items is because it is also a fast method of producing a lot of different products at once.

But there are some drawbacks to pressure casting die. The main challenge is the initial cost can be quite high. This is because the molds have to be constructed extremely carefully and to precise measurements. You are done with data till October 2023 A further limitation is that not all materials can take advantage of pressure casting die. Certain materials are not very well suitable for the high pressure and heat, thus, making it unfeasible to produce some products.

The metal mold is created before the actual pressure casting die process begins. This mold is important because it will be used to form the metal that is going to be melted. The mold has to be very carefully and precisely constructed. Any error or mistake in the molding design leads to an error in the final product through molding process and simulation. That is part of the reason, you need to take time to ensure that the mold was designed correctly.

The next course of action to have metal prepared for injection once the mold is ready. It comes after melting the metal at a really high temperature till it becomes liquid. The high temperature is crucial because it ensures that the metal flows freely when poured into the mold.

After injecting the molten metal, the next step is cold the mold. Cooling enables the metal to set and harden. As soon as the metal cools and hardens, the core is delicately taken out of the cholesterol. This excess metal or material that is not part of the finished product is cut off. This step is necessary for the final item to be clean, and ready to ship.

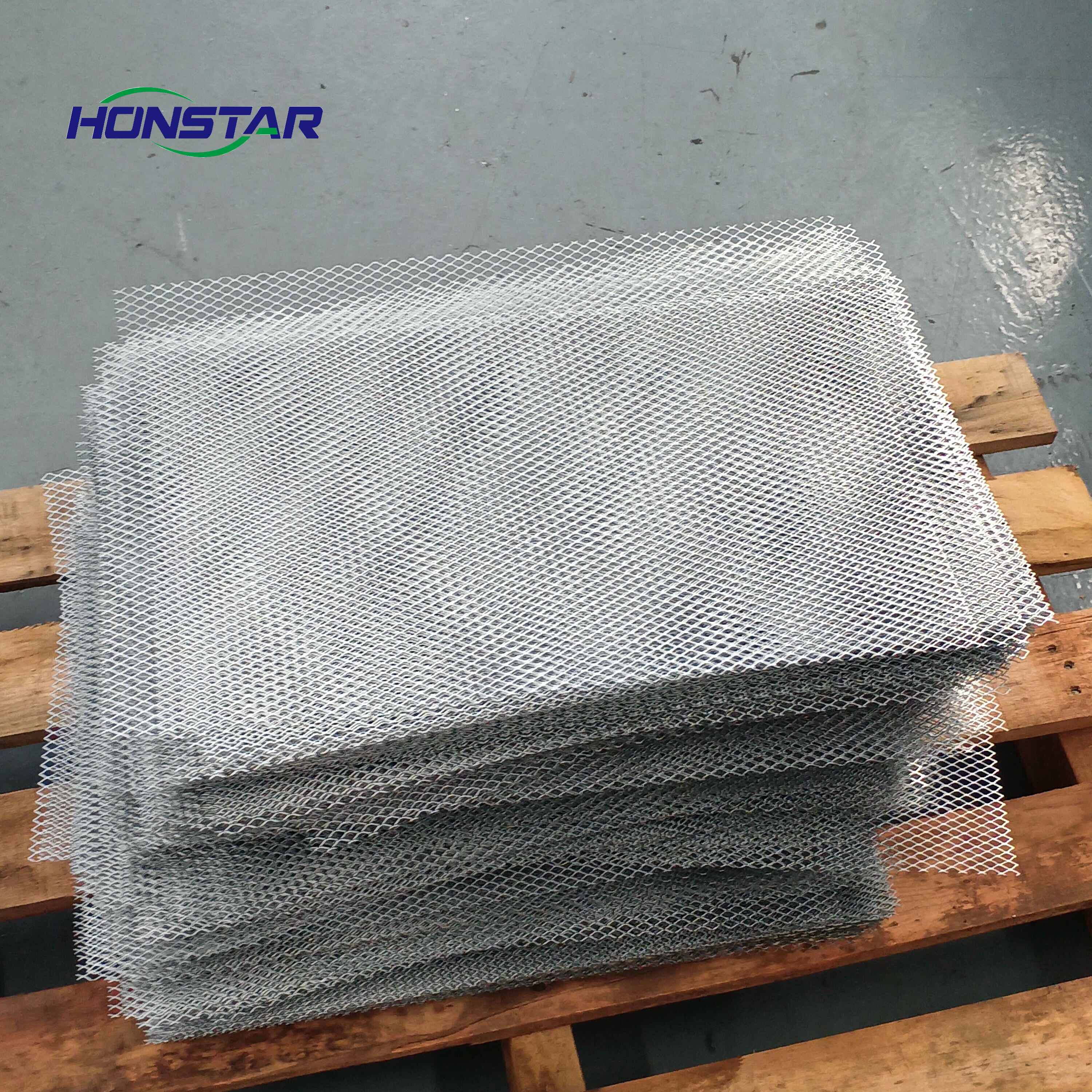

Our company offers more than 2000 kinds of pressure casting die with specifications and sizes that match most of the products available. Our products are made of high quality, which includes stainless steel, iron, and more. The products we offer are able to be used in various applications, and have a major role to play. Additionally, we offer customized products through mold making. We have a highly skilled mold design and development team, which, based on customer drawings and then after discussion and design by the mold development team designs the products customers would like. Other accessories can also be added to existing products the manner that is in line with customer specifications.

Our after-sales services are strong. We provide customers with a wide range of solutions to ensure that the product is able to solve the issues they face. When a buyer purchases a item from us, a few customers may submit packaging requirements, then the packaging of our products will be done in accordance with the needs of customers. Our company offers a free return and exchange service in the event that the product is damaged during transport or has a scratched surface. This allows customers to be more pressure casting die in purchasing our products. The repurchase rate of these products is also high.

Our company is pressure casting die by the ISO9001 quality system certification to ensure that we are able to offer continuous and steady high-quality goods and services by focusing on the fundamentals and methods of quality management, including quality planning, quality control Quality assurance, quality control and improvement. We have implemented this system to guarantee the consistent quality of products and improve customer satisfaction. The goal is to partner with us. We have a sophisticated testing method, a strict management system, an excellent assurance system, and a massive production capacity to ensure that our products' high quality.

Our company's products dominate the majority of the market in this industry in pressure casting die and the raw materials that we use are guarantee. Since the parts used for stamping are produced with molds the mistakes that can occur in traditional processing methods are avoided, and the product's quality is assured. When making items, it is sometimes based on the characteristics of the material the film is positioned on the surface of the material to avoid imperfections or flaws on the surface of the product. By this method established the basis of the quality of our products. They are also highly appreciated by our clients.