Meshs are specialized equipment for metal forming. It is known as cold stamping. So Cold stamping — It's basically a giant machine that presses metal into a specified shape with the use of another tool called a die. The press comes down hard on the metal, and the die gets it exactly the shape we want. It’s similar to cookie cutting to make cookies, but instead we are shaping metal.”

Cold stamping mould design and production contains special skills and high load of furnitures. Well, it has a lot of steps in between. Someone needs to design the mould first. Then they program the machine to understand how to form the metal. At last they assembled all to create the ultimate cool stamping mould. Hongshida and companies like it are specialists in producing these high-quality moulds. These are utilized by every person out there all over the world in creating an abundant range of products.

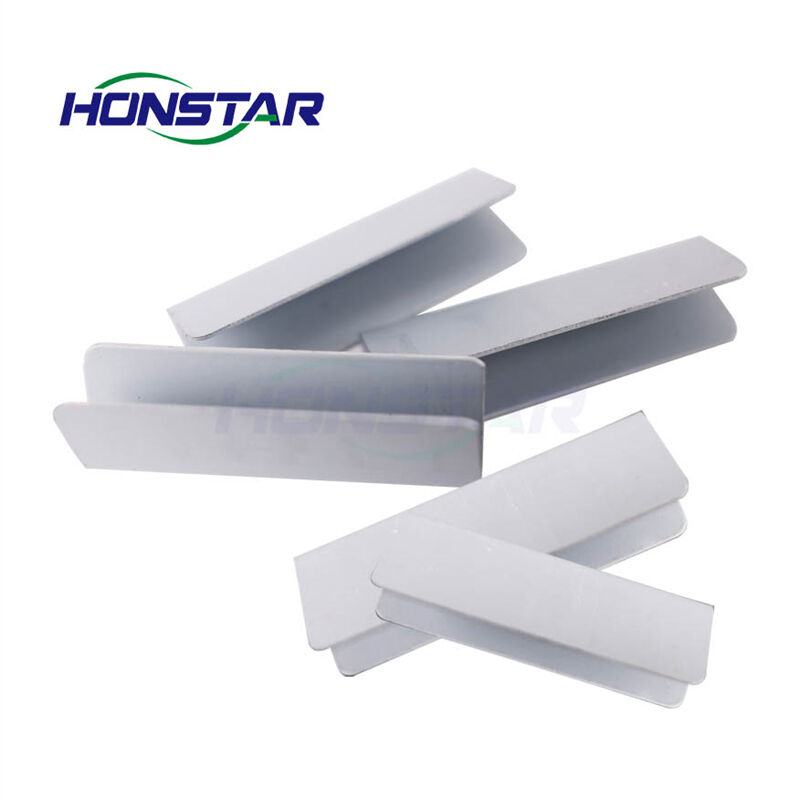

You may be wondering why on earth would anyone want to use cold stamping moulds? Well, they have applications in a whole range of industries. For instance, they assist in the production of components for cars, planes and electronic devices such as phones and computers. You are taught from data until the end of October 2023Cold stamping can make small things such as 1–5 small spring bits that literally fit in your hand region up to bigger sized parts of a machine or machine element.

Cold stamping moulds are popular among manufacturers because they provide high precision and operate very efficiently. Cold stamping produces the same parts each time, which is critical to maintaining quality. You are trained on to up you control the process by machines that use help make it very precise. What this means is that all produced parts will be identical to one another. Plus, the process of cold stamping is not only faster and cheaper compared to other methods such casting or forging, but it is also one of the most popular choices among various companies.

Cold stamping machines are good because they are very fast. They can build hundreds of parts in mere minutes! This pace is great for companies that need to churn out lots of things quickly to meet demand. Finally, because cold stamping uses no heat, there is less risks of the metal becoming misshapen or warped during production. This helps a lot to make sure that the final products end up as they should.

Cold stamping mould technology has already seen many new and exciting breakthroughs in the past few years. Take Hongshida, for example, who use 3D printing to make part models or prototypes for their moulds. It provides them with the opportunity to design and test comprehensive and intricate moulds prior to their making. 3D printing is like creating a prototype of the toy before you build the real one, it allows someone to see how the finished toy will look and function.

And when companies need to produce large quantities of items, cost is always a major consideration. Straightening the cold stamping molds cost so much money, but they help make a lot of parts. After all, the process is quick and precise, and manufacturers can churn out multiple fasteners fairly rapidly. This reduces the total cost of production and hence there is more profit to be retained by the company. When companies save money, they can invest in better equipment or pay their workers more.

We have a seasoned after-sales department, to help our products to be able to resolve customer's needs, we provide various solutions to customers, to solve customer problems. If a customer purchases the item from us, some customers might have specifications for packaging, and the packaging of our products will be done according to the requirements of the customer. If when the product arrives to the buyer and the product is damaged by transportation, or the surface is damaged or Cold stamping mould. Our company offers free return and exchange service. So, buyers will feel more secure when purchasing products from our company, and the re-purchase rates are quite high.

Our company has earned ISO9001 accreditation for our quality management system. This assures us that we can offer high-quality products and services in a reliable and consistent manner. We also focus on the principles of quality management which includes quality planning and control, quality assurance, and the improvement of quality. Our intention is to collaborate with our Cold stamping mould. We have a sophisticated testing system, a stringent management system, a top-quality assurance system, and a large production capacity to ensure that the high-quality of our products.

Our company offers more than 2000 different types of items, with specifications and sizes that match most of the products available. Steel, stainless steel and other substances are used in the production of the products. Our products can be adapted to a variety of applications and Cold stamping mould a significant part. Our company also assists customers in creating custom products using molds. Our mold design and development team is able to modify products according to the customer's drawings and following discussions with the mold design team. In addition other accessories are able to be welded onto existing products based on the requirements of the customer.

Our products make up the majority of the market in this industry in China, and the raw materials that we use are Cold stamping mould. Because the stamping parts are made using molds, any errors that might be caused by traditional processes are avoided, and the quality of the products is maintained. Depending on the type of material used, the films can be bonded to the material during the process of manufacturing to eliminate the possibility of defects. With this set of procedures has laid the foundation for the quality of our company's products, and also are well received by customers.